We are unique

We remain committed to the construction, distribution and specialty products markets. While aluminum producing companies tend to focus in recent times on the aerospace and automotive market, we will continue to make our experience available to the main industrial sectors. We have a clear vision of both our future and the overall contribution that aluminum makes to the world. The long industrial history of the Aludium facilities, opened in the 1950s and constantly renovated since then, provides us with enormous practical experience. Our independence allows us to choose the direction in which we want to move forward and to focus our efforts on the two aspects that we consider essential to guarantee the conservation of the environment: sustainability and recycling.

We are fast

Forget waiting months for a delivery. All Aludium production is made to order. Thanks to the agility of our structure, our sophisticated supply chain and efficient logistics management, we have the ability to respond quickly to all your requests, no matter how complex. The usual wait time is only three to four weeks.

We are a

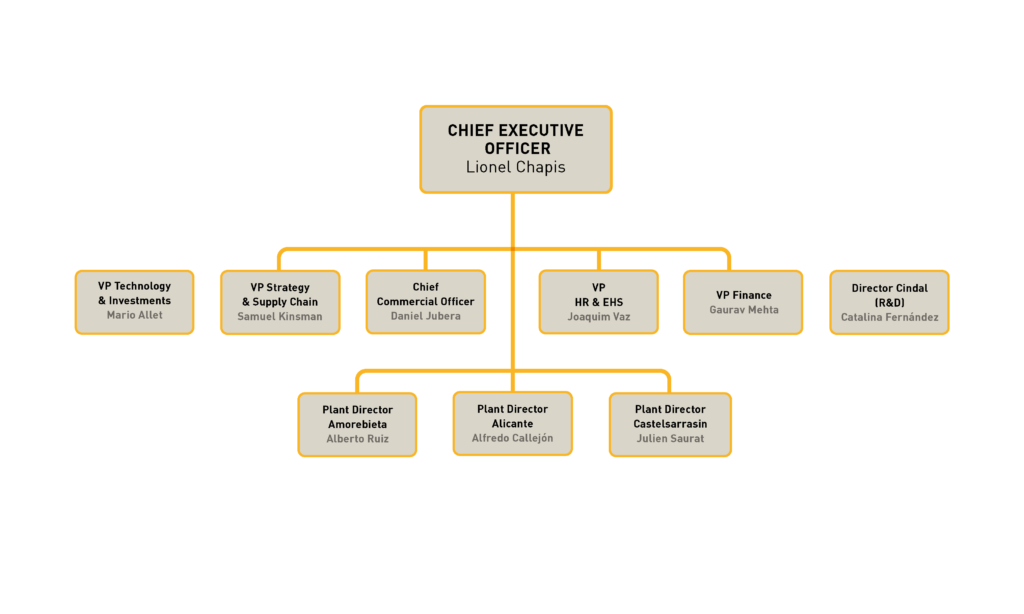

team

Teamwork generates the best results, and ours is led by aluminum veterans a guarantee of success. All Aludium customers can enjoy the best products on the market, as well as excellent care and service.

We are stable

Our company has experienced tremendous growth. All the industrial sectors in which we operate grew during the past year, including the following: construction (facades, structures and fittings), packaging (cosmetics, food and beverages), commercial transport and lighting products (for example, reflectors).

We are experts

Aludium’s exceptional R&D facilities at Cindal advise our customers to help them decide the best alloy for their application and the tools and process required to achieve extraordinary products. In this

center we can develop prototypes for your products and your production processes. You can also count on our R&D team to train your operators in the latest production techniques.

We are passionate

Aludium has a true passion for innovation, for aluminum, for the sectors in which we operate and, above all, for our customers, suppliers and partners. That is what sets us apart. And that difference is the reason why you should choose us as your supplier. Do not hesitate to contact us if you want to place an order or ask any question. You just need to send us an e-mail or call us by phone.